About TIBCON Capacitors

As one of the most renowned manufacturers of Capacitors and MPP Film in India, Tibrewala Electronics Limited (TEL) has successfully reached the elite 25 Million USD segment, having ventured to capture global markets across Asia, Africa, Australia, Europe and America.

With an established presence of nearly three decades in the sector, TEL has become an invaluable resource in the manufacture of industrial machinery and domestic appliances of several reputed international brands and even defence electronics. Presently over 40% of our products are earmarked exclusively for export.

With a staggering investment of over 10 Million USD today, we proudly stand on the threshold of phenomenal outbound growth, adding value to our partners, customers and vendors, strongly contributing to the nation's industrial strength.

TEL has now become the world leader with its rich expertise and global standards.

Quality

TIBCON is a well known brand of capacitors in India for its Performance, Reliability and Durability. The Quality of our products has been a key driver of our growth and prominence in the capacitor industry.

TIBCON Capacitors conform to global industry norms and international standards such as

- ISO 9001-2008

- UL 810 (Underwriters Laboratories)

- CSA (Canadian Standards)

- CE (European- Declaration of Conformity)

- ISI (Indian Standards Institution)

Power Factor Correction Capacitors

The efficiency of power generation, transmission or conversion is improved when operated at near unity power factor. The least expensive way to achieve the same is by installing Power Factor Correction Capacitors. Power factor correction capacitors must be able to withstand high voltage transients and power line variations without breakdown.

TIBCON PFC Capacitors are designed and manufactured for the most demanding applications and toughest ambient conditions. These capacitors are durable, safe, reliable and high performance solution for power factor correction in Industrial & semi-industrial application.

Design & Construction

TIBCON PFC Capacitors are made in accordance with Metallized

Polypropelene technology with built-in SELF HEALING properties.

We mastered this technology over a period of last 30 years and have

the state of art manufacturing facility for metallization of the film. The

elements are wound on fully automatic numerically controlled

winding machine that ensures no corona discharge & ionization.

The elements are housed in cylindrical shaped aluminum case with

in built explosion proof safety device.

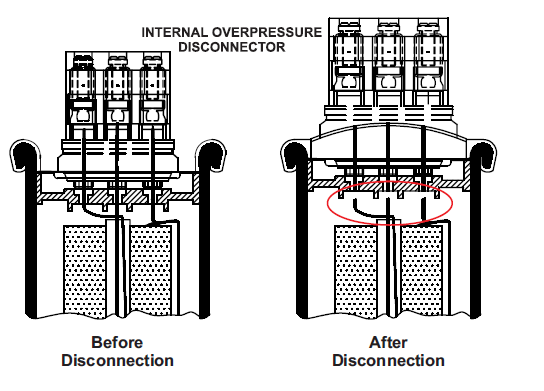

Sometimes Capacitors may explode due to very high voltages in repetitive peaks, which cannot be ‘self healed’ by the regenerative property. TIBCON Capacitors are provided with an internal Over-Pressure Disconnector, which disconnects the capacitor from the power source and prevents it from exploding.

Sometimes Capacitors may explode due to very high voltages in repetitive peaks, which cannot be ‘self healed’ by the regenerative property. TIBCON Capacitors are provided with an internal Over-Pressure Disconnector, which disconnects the capacitor from the power source and prevents it from exploding.

Unique Features

- Compact Cylindrical Construction

- 3 Phase - Delta Connection

- Non-PCB Oil Encapsulation

- High Temperature Withstanding Capacity

- Self Healing Properties

- Explosion Proof Design

- Safe-Touch, Shock-Proof Terminals

- Longer Life Expectancy

- ECO-Friendly

- Wide Range - Standard Duty, Heavy Duty & Super Heavy Duty

Applications

- APFC Control Panels

- Wind Turbines

- Commercial Establishments

- Industrial and Semi Industrial Applications

- De-tuned and Tuned Harmonic Filters

- Fixed Compensation ( Individual and Group)

- Motors and Transformers

- Welding

- Furnaces

Capacitor Types

- Standard / Industrial Duty Power Capcitors

- Heavy Duty Power Capacitors

- Super Heavy Duty Power Capacitors

Standard / Industrial Duty Power Capacitors

^ top

These capacitors are available in both cylindrical and box type variants and are mostly used for fixed or automatic compensation of light loads.

Specifications:

| Range | 1-50 KVAR |

| Type | MKP Cylindrical / MS Box |

| Standard | IEC 60831-1 & 2, IS :13340 PART 1 & 2 |

| Rated Voltage | 230-690 Volts |

| Rated Frequency | 50/ 60 Hz |

| Over Current | 1.5 x I n |

| Inrush Current | 200 x In |

| Discharge Resistor | Special Design Internal Discharge.Resistance 50 V In Less Than 60 Sec |

| Terminals | Three phase terminal with electric shock protection (finger proof), designed for up to 25sq.mm cable termination, Double fast-on with cable (<8kVAr) Tin Plated MS Studs for Box Type Capacitors |

| Capacitance Tolerance | -5% To +10% |

| Test Voltage Terminal to Terminal | Type Test : 2.15 U , 10 Sec, Routine Test : 2.15 U , 2 Sec |

| Test Voltage Terminal to Casing | U≤ 660 V: 3000V AC 10 Sec, U = 660 V :6000V AC 10 Sec |

| Temperature Category | -25°C / + 55°C (Class D) |

| Protection Class/Type | IP20;Dry Type, Self-Healing, Internal Over Pressure Disconnector |

| Life Expectancy | >1,00,000 Operating Hours |

Heavy Duty Power Capacitors

^ top

These capacitors are available in both cylindrical and box type variants and are mostly used for fixed or automatic compensation of light loads.

Specifications:

| Range | 5-30 KVAR |

| Type | MKP Cylindrical / MS Box |

| Standard | IEC 60831-1 & 2, IS :13340 PART 1 & 2 |

| Rated Voltage | 230-690 Volts |

| Rated Frequency | 50/ 60 Hz |

| Over Current | 2.0 x I n |

| Inrush Current | 300 x In |

| Discharge Resistor | Special Design Internal Discharge.Resistance 50 V In Less Than 60 Sec |

| Terminals | Three phase terminal with electric shock protection (finger proof), designed for up to 25sq.mm cable termination, Double fast-on with cable (<8kVAr) Tin Plated MS Studs for Box Type Capacitors |

| Capacitance Tolerance | -5% To +10% |

| Test Voltage Terminal to Terminal | Type Test : 2.15 U , 10 Sec, Routine Test : 2.15 U , 2 Sec |

| Test Voltage Terminal to Casing | U≤ 660 V: 3000V AC 10 Sec, U = 660 V :6000V AC 10 Sec |

| Temperature Category | -25°C / + 55°C (Class D) |

| Protection Class/Type | IP20;Dry Type, Self-Healing, Internal Over Pressure Disconnector |

| Life Expectancy | >1,50,000 Operating Hours |

Super Heavy Duty Power Capacitors

^ top

The Super Heavy Duty Capacitors are made of Internal Series Metallized Film, which will reduce the terminal voltage at the capacitor level by half. This will help in drastic reduction of temperature within the capacitor.

Specifications:

| Range | 5-33 KVAR |

| Type | MKP Cylindrical / MS Box |

| Standard | IEC 60831-1 & 2, IS :13340 PART 1 & 2 |

| Rated Voltage | 230-690 Volts |

| Rated Frequency | 50/ 60 Hz |

| Over Current | 2.7 x I n |

| Inrush Current | 400 x In |

| Discharge Resistor | Special Design Internal Discharge.Resistance 50 V In Less Than 60 Sec |

| Terminals | Three phase terminal with electric shock protection (finger proof), designed for up to 25sq.mm cable termination, Double fast-on with cable (<8kVAr) Tin Plated MS Studs for Box Type Capacitors |

| Capacitance Tolerance | -5% To +10% |

| Test Voltage Terminal to Terminal | Type Test : 2.15 U , 10 Sec, Routine Test : 2.15 U , 2 Sec |

| Test Voltage Terminal to Casing | U≤ 660 V: 3000V AC 10 Sec, U = 660 V :6000V AC 10 Sec |

| Temperature Category | -25°C / + 55°C (Class D) |

| Protection Class/Type | IP20;Dry Type, Self-Healing, Internal Over Pressure Disconnector |

| Life Expectancy | >2,00,000 Operating Hours |